Cementon Bridge, Whitehall, PA

Garrett Hillenbrand, R. E. Pierson Construction Company

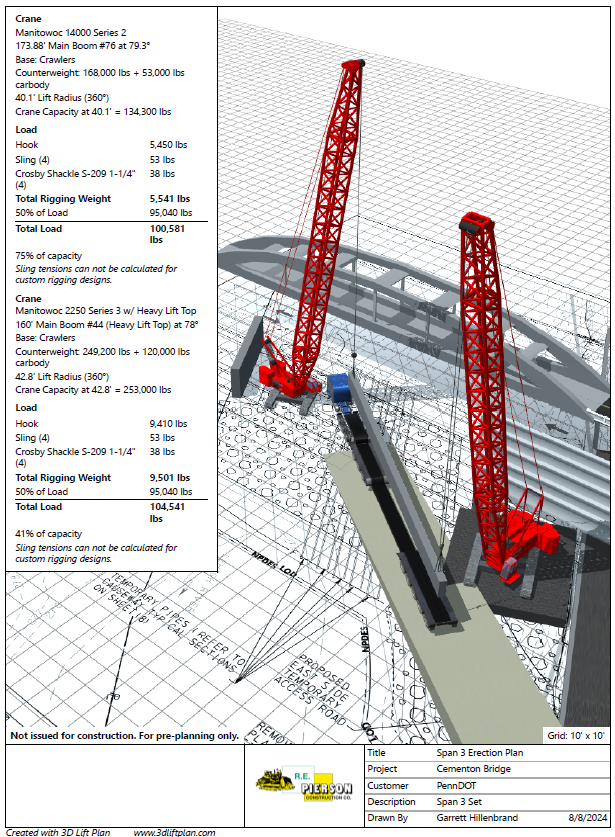

R.E. Pierson was awarded the Cementon Bridge Replacement project for PennDOT. The 580-foot-long bridge crosses the Lehigh River, carrying over 16,000 vehicles daily between the towns of Northampton and Whitehall. The 4 Span bridge has five 33” x 95” Prestressed Concrete Bulb Tee Beams per span that are 145FT long and weight 95 tons each. This project will be completed in stages, with spans 3 and 4 being set in the first stage. Stage 2 requires moving the causeway to the other half of the river to set spans 1 and 2.

Each stage has its own set of challenges. The first stage has limited access for delivery of the beams, and limited locations cranes can sit. There is a historic wall that needs to be preserved, underground utilities that impact crane locations, and train tracks that impact delivery options. Ground pressure from cranes within the program helped avoid conflict with the wall and underground utilities. 3D Lift Plan allowed the team to review several different ideas and determine the most effective way to set the beams. The crane locations utilized for each span also helped show which span needs to be set first.

The second stage of this project has high power transmission lines running 30 feet over the abutment. The electric company will be providing a one-day outage to set beams; however, the lines will not be removed. Several ideas have been reviewed, from single crane picks to skid beams. 3D Lift plan showed us that a 2250 with a 70-foot boom not only has capacity, but also the clearance to safely set the beams. This erection plan will be finalized in 2025.

At the time of bid, the preliminary lift plan consisted of two Manitowoc 2250s to pick the beams. A Manitowoc 14,000 was mobilized at the beginning of this project to build the cofferdams and piers. 3D Lift Plan allowed the cranes to be set up in a variety of locations, showing that the 14,000 has the capacity to pick the beams. Utilizing the 14,000 was a savings to the company by eliminating the mobilization of another crane that is needed on another project.

The ability to import the drawings and accurately create the jobsite in 3D Lift Plan has been helpful to the project. This gave the project team a visual representation of the various lift plans, showing areas of concern or potential conflict prior to getting beams delivered to the jobsite. The ability to create the job to scale shows what site changes would be required prior to getting the beams delivered.

Crews are working diligently to bring this erection plan to fruition. Currently, the beams for Stage 1 are scheduled for an early 2025 delivery.