Warren Towers Roof Replacement Support

Christopher Erickson, Midwest Crane Services

This project was a component of a roof replacement on the Warren #1 & #2 Towers, in lieu of recent damaging winds. The job required multiple cranes to support this project. Our Liebherr LTM 1300-1 and Terex Demag AC250-1 were the obvious choices based on the lift requirements.

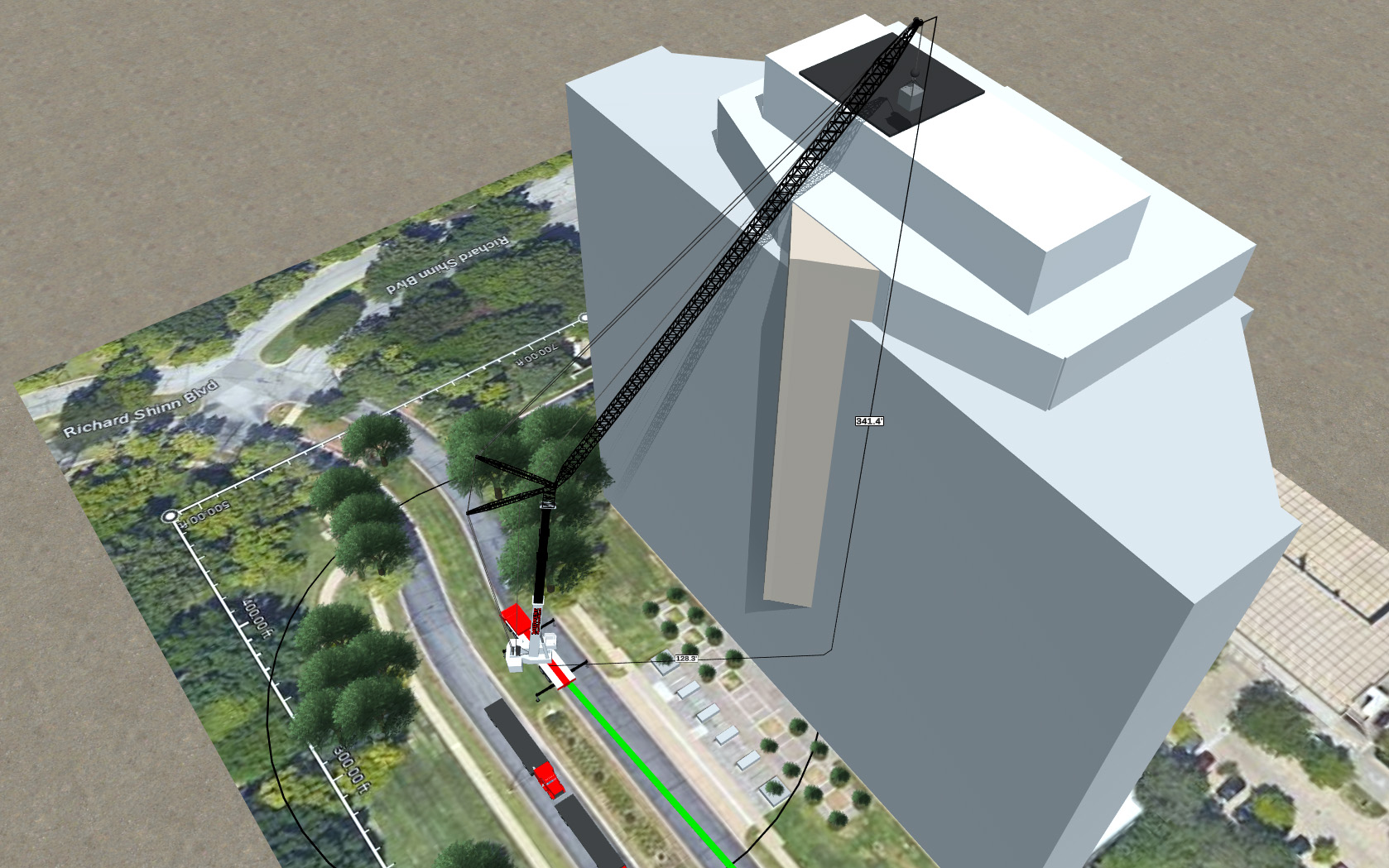

Warren Tower #2 was the first phase of the project. With 192,000lbs of Counterweights, 117’ of Main Boom and 230’ of Luffing Jib, our crew was able to achieve the 130’ lifting radius required to achieve the furthest lift at a maximum height of 310’. The biggest challenges on this project involved building the Luffing Jib and maneuvering the crane and loads of equipment through two one-way streets with built-up trees and decorative gardens surrounding the jobsite. Efficiency and timeliness were key. In order to complete the project with zero disruptions, our Tadano GT-900XL sat on the same side of the road the luffing jib was being built while at the same time reaching to the opposite road to unload the sections off trailers. 3D Lift Plan was utilized to properly determine the exact staging and setup required to avoid critical obstructions, allowing our team to eliminate wasted time. Once setup was completed, all that was left was to support our customer removing and replacing roofing material from the three-tier roof.

The second phase of the project on Warren Tower #1 did not have the same issues working in a forest of trees, but the site had its own set of setup challenges as the crane positioning still needed to allow access to an operational hotel. The space was temporarily blocked to allow for construction of the 92’ of jib to be swung off the end of 253’ of main boom required to achieve the 300’ lift height and 95’ lift radius. As before, 3D Lift Plan was utilized to properly determine the exact staging and setup required to avoid critical obstructions, allowing our team to eliminate wasted time.

The use of 3D Lift Plan on this project was crucial to its success. The ability to visualize crane configurations, both fully erected and in the setup position, in relation to jobsite obstructions proved to be an invaluable resource to both our crew and to our customer. Without it, our vision would not have been easily presented to the owners of the two buildings for space allocation and would have resulted in delays caused by the movements and organization of multiple resources the day of the job. As an engineer, I know how powerful a tool a simulation software can be. Pictures speak a thousand words and 3D Lift Plan is no exception to this saying. Being able to provide our customer with a depiction of his project was more valuable than any phone call or email that could have been provided explaining the plan.